The wafer check valve is less bulky than other types of check valves, being as it is made to fit between a set of flanges. Flanges are usually a plate or ring that forms a rim on a pipe, both internally and externally, and sometimes refers to the raised connecting piece of two pieces of pipe. Therefore, a wafer check valve that can fit easily between flange rims in large plumbing or piping systems is a very useful thing. Read More…

Our check valves are manufactured with the customer in mind. We believe in offering superior products and services every time. No matter whether you are looking for small or large valves, we can meet your every needs. It is our goal to offer excellent prices and service to each customer. Contact us to learn more today!

At Beswick Engineering Co., we are dedicated to engineering precision miniature fluid power components that deliver reliable performance in demanding applications. Our team specializes in designing and manufacturing high-quality check valves, along with an extensive selection of other fluid control products, all crafted to meet tight tolerances and rigorous performance requirements.

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

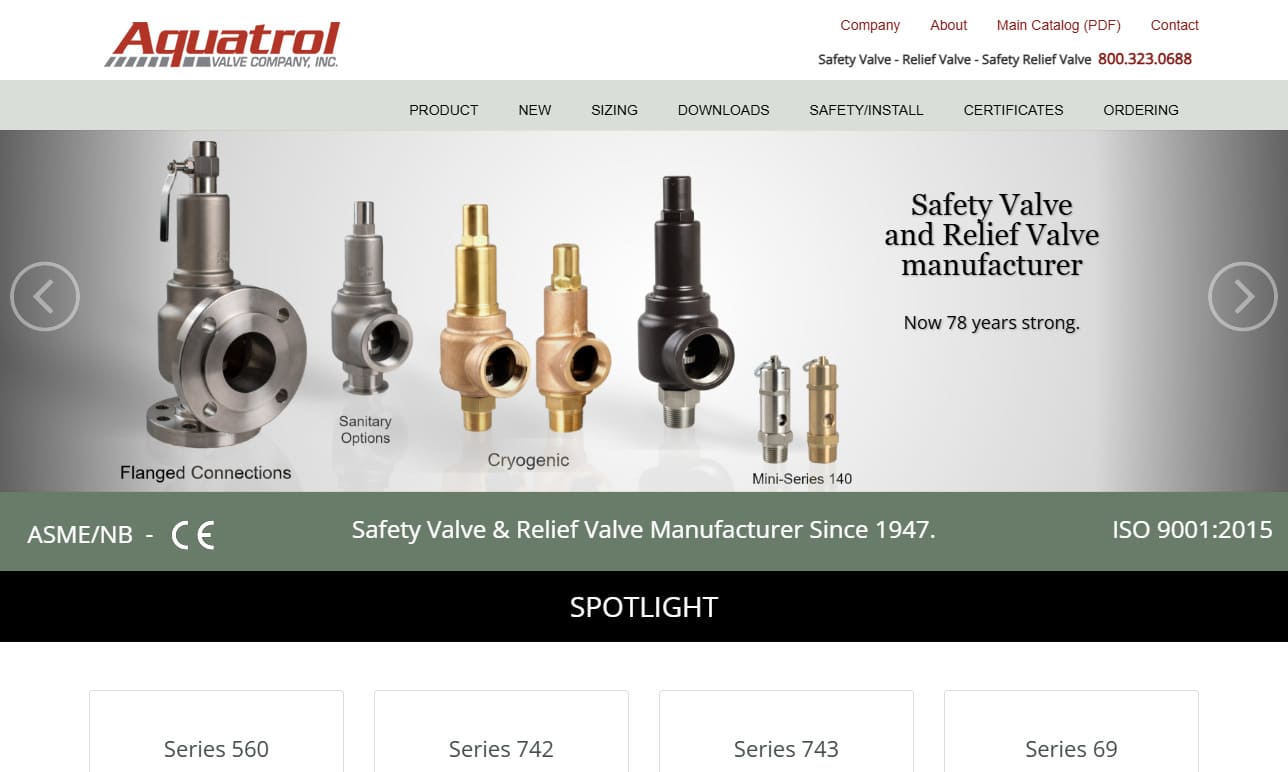

At Aquatrol, we take pride in being a trusted name in the design and manufacturing of high-quality check valves built for durability and precision. With decades of expertise, we have developed a deep understanding of fluid control systems and have dedicated ourselves to engineering solutions that ensure reliability and safety in even the most demanding industrial environments.

At SVF Flow Controls, we take pride in being a trusted manufacturer of precision-engineered flow control products, with a strong emphasis on quality, reliability, and performance. We specialize in the design and production of check valves, ensuring optimal flow management and protection for a wide range of industrial applications.

Offering a full line of flow control products, Plast-O-Matic Valves ensures high quality by testing each of our valve products individually before shipment. We offer plastic check valves, PVC check valves, relief valves, ball check valves and more. We are committed to engineering excellence.

More Wafer Check Valve Manufacturers

Wafer Check Valves: Types, Applications, and Key Benefits

Wafer check valves are critical components in modern piping systems, offering reliable backflow prevention in a wide range of industrial, commercial, and residential applications. Designed for compact installation between pipe flanges, wafer check valves are valued for their slim profile, efficient operation, and cost-effectiveness. This comprehensive guide provides an in-depth look at wafer check valve types, their uses across industries, advantages, selection criteria, and maintenance tips—helping you make an informed decision for your next fluid control project.

What Is a Wafer Check Valve?

A wafer check valve is a type of non-return valve engineered to prevent the reverse flow of fluids (liquids or gases) within a piping system. Its wafer-thin design fits snugly between two flanges, minimizing the space required for installation. Unlike conventional swing check valves, wafer check valves are lighter, more compact, and easier to install, making them a preferred choice for applications where space and weight are critical considerations.

Wafer check valves are available in several configurations:

- Swing-Type Wafer Check Valve: Utilizes a single hinged disc as the moving component. When fluid flows in the intended direction, the disc swings open; reverse flow causes the disc to swing shut, blocking backflow.

- Split Disc (Dual Plate) Wafer Check Valve: Features a flat disc split into two semicircular plates, hinged at the center. This design allows the plates to collapse inward during forward flow and spring outward to seal against backflow. The dual plate valve offers reduced pressure drop and faster response.

- Spring-Assisted Wafer Check Valve: Integrates a spring check valve mechanism to ensure rapid, tight closure, minimizing the risk of fluid leakage or water hammer.

How Does a Wafer Check Valve Work?

Wafer check valves operate automatically, relying on differential pressure. When fluid flows in the desired direction, the pressure lifts or swings the disc open, enabling flow through the valve. If the flow reverses, backpressure pushes the disc closed, forming a seal that prevents fluid from returning. The spring-assisted variant adds a preloaded spring to accelerate closure, improving performance in high-cycling or vertical installations.

Wondering which type of wafer check valve is best for your application? Ask yourself:

- What is the fluid type and operating pressure?

- Is rapid closure to prevent water hammer critical?

- Do you need a low-pressure drop solution for energy efficiency?

- What are the installation space and weight constraints?

Common Applications of Wafer Check Valves

Wafer check valves are trusted across diverse industries, thanks to their versatility and robust performance. Typical applications include:

- Boiler Feedlines: Protects against backflow in high-temperature, high-pressure environments, ensuring safe and efficient boiler operation.

- Hot Water Circuits: Maintains correct flow direction in heating systems, preventing reverse circulation.

- Vacuum Breakers: Prevents vacuum formation and back-siphonage, safeguarding potable water supplies. Commonly used in toilets, urinals, and other sanitary drainage systems.

- Steam Traps and Blowdown Vessels: Ensures steam and condensate flow as designed, improving system efficiency and safety.

- Flash Vessels: Facilitates the rapid separation of vapor and liquid during flash evaporation, a process vital in oil refineries, air-conditioning and refrigeration systems, and natural gas processing plants.

- Chemical Processing: Prevents cross-contamination of chemicals and unwanted reverse flow in corrosive or hazardous environments.

- Power Generation: Used in cooling water systems, condensate lines, and turbine protection circuits.

- Municipal Water and Wastewater Treatment: Provides backflow protection to maintain water quality and prevent contamination.

- Fire Protection Systems: Ensures the integrity of fire suppression lines by preventing reverse flow.

Not sure if a wafer check valve is right for your project? Explore our application guides or contact our technical team for expert advice.

Industry Sectors That Rely on Wafer Check Valves

Wafer check valves are integral to:

- Oil and Gas: Used in upstream, midstream, and downstream operations for safe, reliable flow control.

- Chemical & Petrochemical Plants: Handles aggressive chemicals and high temperatures with corrosion-resistant materials.

- Power Plants: Applied in steam, cooling, and condensate systems for optimal efficiency and safety.

- Water Treatment Facilities: Ensures unidirectional flow in clean and wastewater lines.

- HVAC and Building Services: Maintains proper flow in heating, ventilation, and air conditioning systems.

- Food & Beverage Processing: Used in sanitary applications where contamination prevention is critical.

- Pharmaceutical Manufacturing: Complies with stringent hygiene and quality standards.

Advantages of Wafer Check Valves

Wafer check valves offer numerous benefits that enhance operational efficiency, safety, and cost control:

- Compact and Lightweight Design: Saves space and reduces load on piping supports, ideal for retrofits and tight installations.

- Ease of Installation: Simple to fit between flanges without complex mounting hardware or extensive modifications.

- Low Pressure Drop: Streamlined flow path minimizes energy losses, supporting energy-efficient system design.

- Cost-Effective: Generally more affordable than full-bodied swing check valves, with lower maintenance requirements.

- Automatic Operation: No manual intervention required—minimizing labor costs and reducing the risk of human error.

- Versatile Sizing: Available in a wide range of diameters and pressure classes to suit virtually any application.

- Durable Construction: Manufactured from robust materials such as stainless steel, carbon steel, bronze, and exotic alloys for longevity in harsh environments.

- Leakage Prevention: Spring-assisted designs ensure tight shutoff, even in low-flow or vertical piping arrangements.

Curious about the difference between wafer check valves and other check valve types? Compare wafer, swing, and lift check valves in our detailed valve comparison guide.

Wafer Check Valve Selection: Critical Factors and Buyer Considerations

Choosing the right wafer check valve for your process requires careful evaluation of technical and operational requirements. Key decision factors include:

- Material Compatibility: Select body and disc materials that resist corrosion and degradation from the process fluid. Stainless steel, duplex alloys, and polymers are common options.

- Pressure Rating: Ensure the valve is rated for the maximum system pressure and temperature.

- Flow Characteristics: Consider the required flow rate, pressure drop, and potential for water hammer. Dual plate or spring-loaded wafer check valves often offer superior performance in high-cycle or fast-closing applications.

- Installation Orientation: Some wafer check valves are suitable for horizontal, vertical, or inclined installations—verify compatibility.

- End Connection: Verify that the wafer check valve matches the flange standards (e.g., ANSI, DIN, JIS) of your piping system.

- Size and Weight: Evaluate space constraints and support structures, especially in retrofits or compact systems.

- Industry Certifications: For sanitary, food, or pharmaceutical use, confirm compliance with relevant standards such as FDA, EN, or ASME BPE.

Ready to specify a wafer check valve? Review our wafer check valve specification checklist for step-by-step guidance.

Wafer Check Valve Maintenance and Troubleshooting

Proper maintenance ensures reliable operation and extends the service life of wafer check valves. Follow these best practices:

- Regular Inspection: Periodically check for signs of wear, corrosion, or debris accumulation on the disc, hinge, and seating surfaces.

- Cleaning: Flush the valve as needed to prevent buildup of solids or contaminants, especially in slurry or dirty service applications.

- Seal Replacement: Replace worn or damaged seals to maintain leak-tight performance.

- Functional Testing: Test valve response under normal and reverse flow conditions during scheduled shutdowns.

- Record Keeping: Maintain logs of inspection, maintenance, and repairs to track performance over time.

Experiencing issues such as leakage, chattering, or premature wear? Consult our wafer check valve troubleshooting guide for practical solutions.

Wafer Check Valve vs. Other Check Valve Types: Which Should You Choose?

When evaluating check valves for your operation, it’s important to weigh the pros and cons of wafer check valves against other models, such as swing check valves, lift check valves, and ball check valves. Consider wafer check valves when space constraints, weight reduction, or energy efficiency are top priorities. However, in applications with severe fouling, high solids content, or where a full-port design is needed, other valve styles may be preferable.

Typical comparison criteria include:

- Installation Space (wafer check valves are the slimmest option)

- Pressure Drop (dual plate and swing wafer designs minimize losses)

- Closure Speed (spring-assisted wafer valves outperform swing models)

- Sealing Tightness (spring-loaded and elastomer-seated designs offer best-in-class leakage prevention)

- Maintenance Access (wafer check valves are easy to remove and inspect)

Still deciding? See our resource center for detailed check valve selection guides and application notes.

Frequently Asked Questions About Wafer Check Valves

- What’s the difference between a wafer check valve and a swing check valve?

While both types prevent backflow, wafer check valves are thinner and lighter, designed to fit between flanges, whereas swing check valves have a bulkier body. Wafer check valves are ideal where space and weight are limited. - Can wafer check valves be installed vertically?

Yes, many wafer check valves are suitable for both horizontal and vertical installations. Always verify the manufacturer’s recommendations to ensure proper operation in your orientation. - How do I select the correct size wafer check valve?

Size selection depends on pipe diameter, flow rate, and pressure drop requirements. Consult flow charts and engineering data for precise sizing. - What materials are available for wafer check valves?

Common materials include stainless steel, carbon steel, ductile iron, bronze, and high-performance alloys. Seat and seal options vary—choose based on fluid compatibility. - How can I prevent water hammer with a wafer check valve?

Spring-assisted wafer check valves close quickly, reducing the risk of water hammer. Proper sizing and installation also help mitigate this issue.

Why Choose Us for Your Wafer Check Valve Needs?

We are a trusted supplier of premium wafer check valves, offering a full range of sizes, pressure ratings, and material options to meet the needs of today’s industries. Our technical experts provide personalized consultation, helping you choose the optimal valve for your specific process requirements. All products are manufactured to the highest standards of quality and performance, with fast delivery and comprehensive after-sales support.

Ready to get started? Request a quote today or speak with our engineering team for application-specific recommendations.

Looking for more information? Explore our in-depth articles, product catalogs, and technical datasheets to ensure you find the best wafer check valve solution for your application.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services