A swing check valve consists of a valve core, seat, and disk connected to a hinge. The disk spins to a horizontal plane to allow onward flow when the flow rate reaches a predetermined level. When the flow is stopped, the disk travels to the valve plate to stop any backflow. Read More…

Our check valves are manufactured with the customer in mind. We believe in offering superior products and services every time. No matter whether you are looking for small or large valves, we can meet your every needs. It is our goal to offer excellent prices and service to each customer. Contact us to learn more today!

At Allied Group USA, we present ourselves as a dependable provider of check valves engineered to ensure reliable flow control, system protection, and long-term performance in demanding applications. We focus on supplying valves that prevent backflow, maintain pressure integrity, and support safe, efficient operation across a wide range of industrial systems.

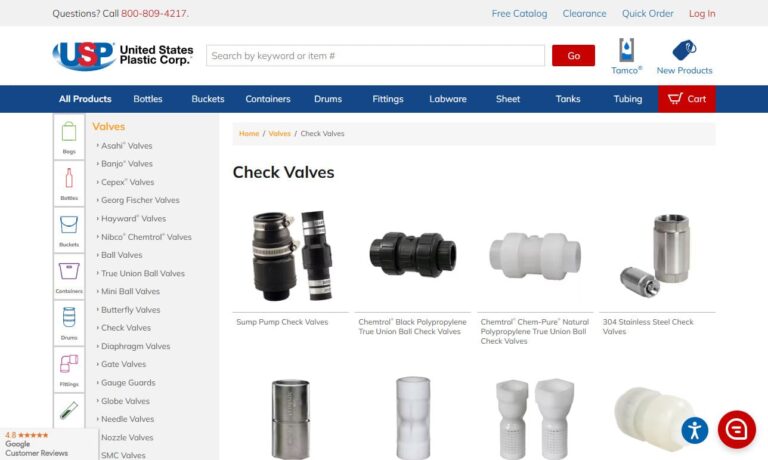

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

At IER Fujikura, we define ourselves as a dedicated manufacturer of check valves engineered to deliver reliable, consistent, and long-lasting flow control performance across a wide range of industries. We work with high-quality materials and precision manufacturing techniques to produce valves that maintain tight sealing, smooth operation, and dependable resistance to pressure fluctuations and...

At Strataflo Products Inc., we present ourselves as a dedicated manufacturer of check valves engineered to deliver dependable flow control, system protection, and long-term reliability in demanding industrial applications. We design our valves to prevent backflow, maintain pressure stability, and support smooth, efficient operation in fluid handling systems where performance and durability are...

Offering a full line of flow control products, Plast-O-Matic Valves ensures high quality by testing each of our valve products individually before shipment. We offer plastic check valves, PVC check valves, relief valves, ball check valves and more. We are committed to engineering excellence.

More Swing Check Valve Manufacturers

Due to their swinging disks, swing check valves can only handle horizontal or vertical upward flows. A swing check valve’s use is limited because it can't support downward flow. Despite this drawback, swing check valves are capable of handling huge flow capacities. Swing check valves provide low flowing and flow pressure resistance.

Operating Principles

Swing check valves open in one direction and close themselves when the pressure at the cracking point (the minimum level of pressure required to open the valve) drops. Swing check valves have a disk covering their opening, making them a type of butterfly valve. The disk is fastened to a hinge, allowing it to move open or shut in response to media flow. The valve’s body features an arrow that points which direction the fluid will flow as it enters and leaves the valve. The flow's pressure level forces the disk open, allowing a liquid stream to pass through. The pressure of the fluid or media pushing on the disk causes it to close when the flow is going in the wrong direction. The disk and rocker of the swing control valve are connected, allowing them to rotate at an angle about the pin shaft. Fluid flows in the designated direction when the intake force to the disk is greater than the resistance pressure. As the valve opens, the disk disengages from its seat and revolves around the shaft to the fully open position. The valve disk then spins back to the shut position as soon as the flow rate decreases. This disk movement stops fluid from flowing backward.

Types of Swing Check Valves

Swing check valves come in a variety of designs that can be broadly divided into tilting-disk and top-hinged categories. All swing check valves use a similar operational process. The primary distinction between these two groupings is the manner in which the valve disk is extended.

Top-Hinged Swing Check Valves

The top-hinged variation is the most prevalent type of swing check valve. The disk can open and close in a swing check valve by hinging to the interior top of the valve. The disk is situated on the rim of a fully-developed turbulent flow profile when it swings open.

Tilting-Disk Swing Check Valves

A tilting-disk swing check valve opens at lower flows and closes more quickly than other swing check valves. This speedier shutting lessens the water hammer effect (a pressure surge that results when a fluid is abruptly forced to change or stop movement) when there is reverse flow. After a tilting disk valve opens, its disk remains in the flow path.

Straight Swing Check Valves

A straight swing check valve features a horizontally-mounted disk that swings on a hinge pin. The pressure of an upstream flow opens the valve as a fluid passes through. This valve closes when the pressure drops. The disk lies on a seat ring to make a tight, uniform seal when a straight swing check valve is closed. A straight swing check valve’s seating surface is slightly angled to operate at lower pressures, create a good seal, and reduce shock when shutting.

Applications

- Swing check valves are typically installed in pipelines to move water, chemical, and petroleum products.

- Swing check valves can control and move corrosive media such as solid oxidizing agents, nitric acid, oil, and acetic acid.

- Swing check valves work better with clearer fluids over thicker, viscosity- or solid-intensive environments.

- Swing check valves are often used in water pumping and wastewater treatment applications because they perform effectively with big, predictable flows.

- Swing check valves provide reliable service for pure process media in general.

Connectors for Swing Check Valves

Threaded Connectors

Swing check valves with threaded connections are the most common connection mechanism for pipes in low-pressure systems. These valves bolt onto threaded pipes to create a secure and tight connection, as the term threaded suggests.

Flanged Connectors

Flanged connectors provide the strongest connections for swing check valves and may be used with any network, regardless of valve size or press. This variety of swing check valve features twin flanges bolted together, one at their outlet and one at their inlet.

Press Fittings

Press fittings may be used as a substitute for welding and soldering valves to pipes. Press fittings are specially-made connectors designed to attach swingcheck valves to pipelines using a hydraulic tool. Press fittings feature a sealing element that forms a consistent, dependable connection when pressed. Press fittings are also called press and crimping connectors.

Sweat Fittings

The valve holes on a swing check valve are slightly bigger than the pipe sizes they work with. Therefore, swing check valves are coated with solder (“sweat”) that drips into the spaces between a pipe as it is slid onto the pipe. Sweat fittings are most commonly used with copper piping.

Choosing the Right Swing Check Valve Supplier

To ensure the best outcome when purchasing swing check valves from a swing check valve company, it is critical to compare several companies using our directory of swing check valve suppliers. Each swing check valve supplier has a business profile page highlighting their areas of expertise and capabilities, along with a contact form to directly communicate with them for more information or to request a quote. Review each swing check valve business website using our patented website previewer to get an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple swing check valve businesses using the same form.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services