A form of ball valve where the ball is forced to move by pressure from gases or liquids is a ball check valve. The valve automatically closes when the fluid’s pressure on the ball ends. The seat is manufactured to fit the ball, while the chamber is formed conically to help the ball enter the seat to seal and stop a reverse flow. Lighter balls can be chosen if the pump’s capacity is insufficient, while heavier balls can be chosen if the water hammer occurs after the pump stops. Read More…

Our check valves are manufactured with the customer in mind. We believe in offering superior products and services every time. No matter whether you are looking for small or large valves, we can meet your every needs. It is our goal to offer excellent prices and service to each customer. Contact us to learn more today!

At Beswick Engineering Co., we are dedicated to engineering precision miniature fluid power components that deliver reliable performance in demanding applications. Our team specializes in designing and manufacturing high-quality check valves, along with an extensive selection of other fluid control products, all crafted to meet tight tolerances and rigorous performance requirements.

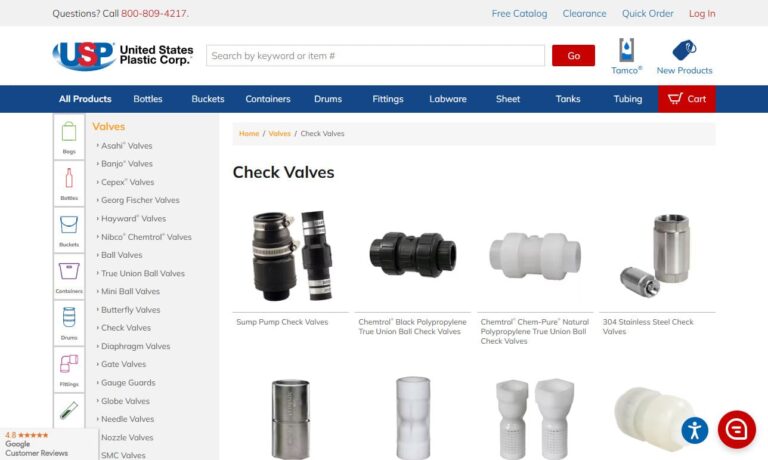

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

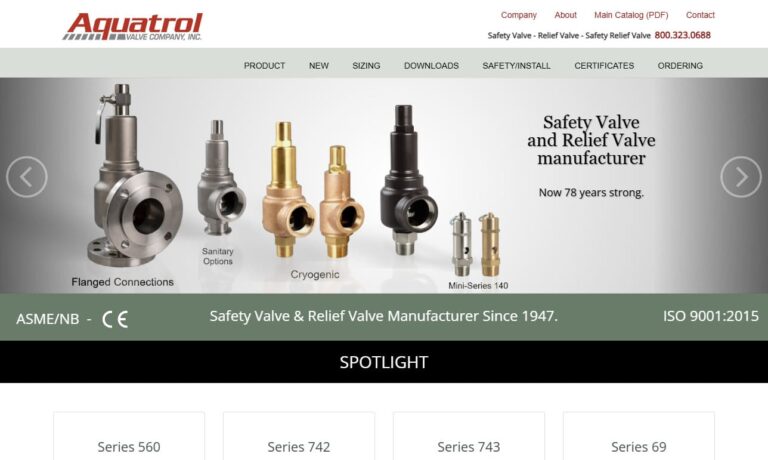

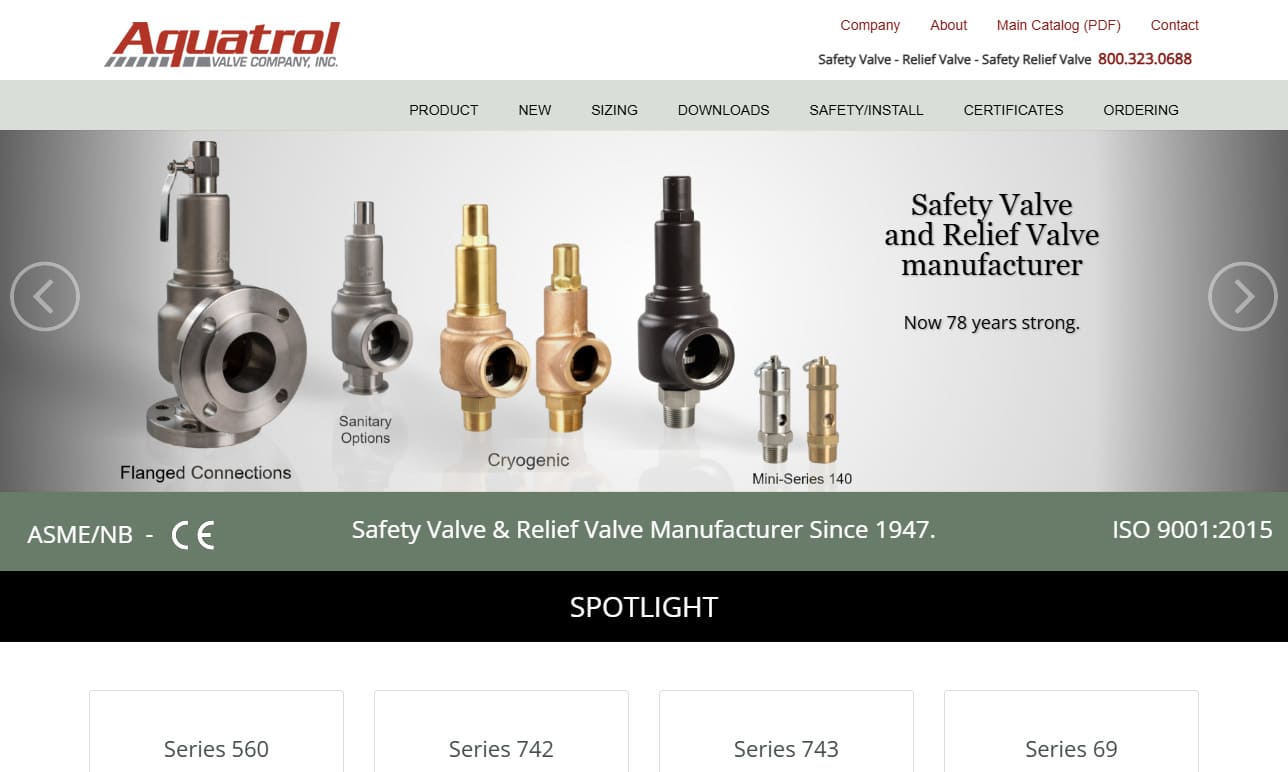

At Aquatrol, we take pride in being a trusted name in the design and manufacturing of high-quality check valves built for durability and precision. With decades of expertise, we have developed a deep understanding of fluid control systems and have dedicated ourselves to engineering solutions that ensure reliability and safety in even the most demanding industrial environments.

At SVF Flow Controls, we take pride in being a trusted manufacturer of precision-engineered flow control products, with a strong emphasis on quality, reliability, and performance. We specialize in the design and production of check valves, ensuring optimal flow management and protection for a wide range of industrial applications.

Offering a full line of flow control products, Plast-O-Matic Valves ensures high quality by testing each of our valve products individually before shipment. We offer plastic check valves, PVC check valves, relief valves, ball check valves and more. We are committed to engineering excellence.

More Ball Check Valve Manufacturers

Design of Ball Check Valves

Ball check valves are an essential type of two-port, non-return valve designed to automatically prevent the backflow of liquids or gases in a piping system. As self-activating devices, their design supports a multitude of industrial and commercial applications—from potable water systems to chemical processing, HVAC, and wastewater management. These one-way valves are engineered for reliability, minimal maintenance, and a compact footprint, making them a preferred solution for flow control and backflow prevention.

Structurally, a standard ball check valve consists of four primary components:

- Valve Body/Pipe: The main enclosure that houses the working parts and provides the connection points for pipeline integration.

- Ball: The movable element that acts as the sealing mechanism. The ball is typically made of materials compatible with the process media, such as rubber, stainless steel, or even ceramics for corrosive environments.

- Valve Seat: The precisely machined surface upon which the ball rests to form a tight seal, preventing reverse flow.

- Conical Spring: Used in many designs to ensure the ball returns promptly to the closed position, especially in vertical installations or applications subject to intermittent flow.

During operation, fluid or gas pressure entering the valve lifts the ball off the seat, allowing forward flow. When flow ceases or reverses, gravity and/or the spring mechanism return the ball to its seat, instantly blocking backflow. This automatic function is critical for maintaining system integrity and preventing contamination in sensitive applications.

Ball check valves are commonly constructed from robust materials such as brass, stainless steel, PVC, and polypropylene, depending on the chemical compatibility, temperature range, and pressure requirements of the application. Specialized coatings and elastomers can further enhance resistance to aggressive media, ensuring longevity and consistent performance.

Key Considerations in Ball Check Valve Selection

Choosing the right ball check valve is crucial for optimal system performance, reliability, and cost-effectiveness. The following factors are essential in the selection process:

Operating Conditions

Assessing the operating temperature, system pressure, and installation orientation is fundamental. High-temperature environments, such as steam or hot water lines, demand materials like brass or stainless steel for thermal stability. In corrosive or chemically aggressive settings, consider valves made of PVC or with special linings.

- Question: Are you searching for a ball check valve that can withstand high temperatures or corrosive chemicals?

Life Expectancy & Maintenance Requirements

Long-term reliability and minimal maintenance are hallmarks of quality ball check valves. Stainless steel models, for example, offer superior resistance to abrasion, pressure, and temperature fluctuations, resulting in extended service life and reduced downtime. Evaluate the expected duty cycle and environmental conditions to select a valve with an appropriate maintenance profile.

- Prompt: Compare the maintenance intervals and service life of different ball check valve models to determine the best fit for your process.

Media Compatibility

The chemical properties of the working medium are critical in material selection. For aggressive or corrosive fluids and gases, PVC ball check valves or those with fluoropolymer linings are recommended. For potable water or food-grade applications, opt for valves with NSF-approved materials. Note that pressure ratings can vary significantly with material choice.

- Prompt: What type of media—water, oil, steam, gas, acids, or slurries—will your ball check valve control?

Pressure Drop and Flow Rate

Understanding pressure drop across the valve is vital for system efficiency. Ball check valves are designed to minimize resistance to forward flow while ensuring a tight seal against backflow. Ensure that the selected valve maintains acceptable pressure loss and supports your required maximum flow rate. The minimum differential pressure needed to open the valve and the maximum allowable working pressure must be carefully matched to your system’s specifications.

- Question: How does the pressure drop across a ball check valve impact your overall system performance?

Control Mechanism

Ball check valves utilize gravity, spring force, back pressure, or a hybrid mechanism to control the ball's movement. Select a valve with the appropriate actuation for your installation—vertical pipe runs may benefit from spring-assisted designs, while horizontal installations may rely solely on gravity and pressure differential. The optimal valve should offer unrestricted forward flow and absolute backflow prevention.

- Prompt: Do you need a spring-loaded ball check valve for rapid response or a gravity-based design for low-pressure applications?

Types of Ball Check Valve Connections

Ball check valves are available with a variety of connection types to suit different piping systems and installation preferences. Selecting the right connection ensures leak-free integration and compliance with industry standards.

- Flanged Ball Check Valves: Feature standardized inlet and outlet flanges, often per EN 1092-2 or ANSI B16.5, ensuring robust attachment in industrial piping. They are common in plumbing, fire protection, HVAC, water, and sewage treatment systems.

- Threaded Ball Check Valves: Provide internal (female) or external (male) threads for versatile connection to pipes, fittings, or equipment. Ideal for smaller pipe diameters and easy maintenance.

- Soldered Ball Check Valves: Designed with ends suitable for soldering directly to copper tubing, frequently used in domestic water supply and heating applications.

- Compression Fitting Ball Check Valves: Enable secure, leak-proof connections without the need for soldering or threading—widely used in residential and light commercial systems for fast installation.

- Buttweld Ball Check Valves: Offer seamless integration with welded piping systems, providing superior strength and integrity, especially in high-pressure or high-temperature process lines.

Industrial and Commercial Uses of Ball Check Valves

Ball check valves play a critical role in diverse industries, providing automatic backflow prevention and process protection. Their versatility allows them to be deployed in:

- Sprinkler and piping systems: Prevents reverse flow and keeps fire suppression and irrigation systems primed for rapid response.

- Water supply and distribution: Stops contaminated water from re-entering clean water lines, protecting potable water quality.

- Industrial process equipment: Used in pump discharge lines, chemical dosing systems, and air/gas compressors to safeguard equipment and maintain process integrity.

- Medical and laboratory devices: Essential in liquid pump dispensers, sprayers, and precision dosing equipment to ensure controlled, one-way fluid movement.

- Injection molding machinery: Maintains unidirectional flow of molten plastics, preventing costly defects and optimizing product quality.

- Wastewater and sewage treatment: Prevents sewage backflow, protecting infrastructure and the environment from contamination.

- Oil and gas pipelines: Used to avoid contamination and maintain flow direction in critical transport infrastructure.

Looking for application-specific recommendations? What challenges are you trying to solve with a ball check valve—contamination, pump protection, or system efficiency?

Benefits and Advantages of Ball Check Valves

Modern ball check valves offer a host of benefits that make them a popular choice for flow control and safety across industries:

- Compact Size: Their small form factor allows installation in tight spaces and retrofitting into existing piping systems.

- Ease of Operation: No manual intervention is required; ball check valves operate automatically based on system pressure.

- Cost-Effectiveness: Simple construction and minimal moving parts result in lower purchase and maintenance costs compared to more complex valves.

- Versatile Installation: Suitable for both vertical and horizontal pipe runs, accommodating a wide range of system designs.

- Media Flexibility: Handles liquids, gases, slurries, and even viscous fluids in applications with high pressure and large flow rates.

- Self-Cleaning Action: The rolling or rotating motion of the ball helps prevent sediment buildup and ensures consistent sealing performance over time.

- Reusable Seat Rings: Many designs allow for easy seat replacement, further extending valve service life and reducing total cost of ownership.

- Fast Response: The simple mechanism ensures rapid closure in the event of backflow, protecting equipment and preventing system contamination.

- Leak-Tight Seal: The ball and seat interface delivers reliable, bubble-tight shutoff, even after repeated cycling.

Common Questions and Key Decision Factors When Purchasing Ball Check Valves

When evaluating ball check valves for your project or facility, consider these crucial questions to ensure the best fit for your needs:

- What is the maximum working pressure and temperature for your application?

- Is chemical compatibility with your process media required? If so, which materials are recommended?

- What pipe connection type best suits your installation—flanged, threaded, soldered, compression, or buttweld?

- Are there specific regulatory or sanitary requirements, such as NSF, FDA, or UL certifications?

- Will the valve be installed in a vertical or horizontal orientation, and does this affect your choice of mechanism (spring-loaded vs. gravity)?

- How important are features like low cracking pressure, self-cleaning action, or ease of maintenance in your application?

- Does your project require a quick lead time or custom fabrication options?

Prompt: Need help sizing or specifying a ball check valve for your system? Contact our experts for personalized recommendations and technical support.

Choosing the Right Ball Check Valve Supplier

Partnering with a trusted ball check valve manufacturer or distributor is vital for acquiring quality products that meet your project’s technical and regulatory requirements. When sourcing ball check valves, always compare multiple suppliers to assess:

- Product Range: Does the manufacturer offer the full spectrum of sizes, materials, and connection types to satisfy your application?

- Certifications and Compliance: Do their products meet relevant standards, such as ISO, ANSI, NSF, or API?

- Technical Support: Are engineering resources available to assist with sizing, selection, and troubleshooting?

- Lead Time and Delivery: Can the supplier accommodate your project schedule and offer fast shipping or inventory availability?

- Customization: Do they provide custom solutions, special coatings, or unique end connections upon request?

To guarantee the best outcome when purchasing ball check valves, leverage our comprehensive directory of ball check valve companies. Each manufacturer profile details their core competencies, certifications, and product specializations. Use our easy-to-navigate RFQ form to request quotes from multiple suppliers, ensuring you receive competitive pricing and responsive service. Review their websites using our patented preview tool to evaluate quality, expertise, and manufacturing capabilities before making your decision.

Explore Related Check Valve Types and Further Resources

While ball check valves are highly versatile, other check valve types may better suit certain applications. Explore these related solutions to find the ideal valve for your needs:

- Swing Check Valves – Featuring a hinged disc for low-pressure drop in gravity-fed systems.

- Lift Check Valves – Ideal for high-pressure, high-velocity flow where tight shutoff is essential.

- PVC Check Valves – Lightweight, corrosion-resistant options for water treatment and chemical processing.

Conclusion: Maximizing Value from Your Ball Check Valve Investment

Ball check valves are a cost-effective, reliable solution for unidirectional flow control and automatic backflow prevention in a wide range of industries. Their robust design, minimal maintenance requirements, and adaptability to diverse media—water, oil, gas, chemicals—make them an indispensable component in modern fluid handling systems. By understanding your system’s requirements, evaluating key decision factors, and partnering with a reputable supplier, you can ensure long-lasting performance, operational safety, and regulatory compliance.

Ready to select the perfect ball check valve for your project? Ask our experts, request a quote, or explore our directory for the top manufacturers and suppliers in the industry. Your next step toward dependable flow control starts here.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services