Check valves are self-activating relief valves. They operate entirely by reacting to the flow and pressure generated by the process streams in which they are installed. Also known as one-way directional or non-return valves, these devices are designed to allow fluid, air or gases to flow in only one direction and eliminate backflow. Read More…

Our check valves are manufactured with the customer in mind. We believe in offering superior products and services every time. No matter whether you are looking for small or large valves, we can meet your every needs. It is our goal to offer excellent prices and service to each customer. Contact us to learn more today!

At Beswick Engineering Co., we are dedicated to engineering precision miniature fluid power components that deliver reliable performance in demanding applications. Our team specializes in designing and manufacturing high-quality check valves, along with an extensive selection of other fluid control products, all crafted to meet tight tolerances and rigorous performance requirements.

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

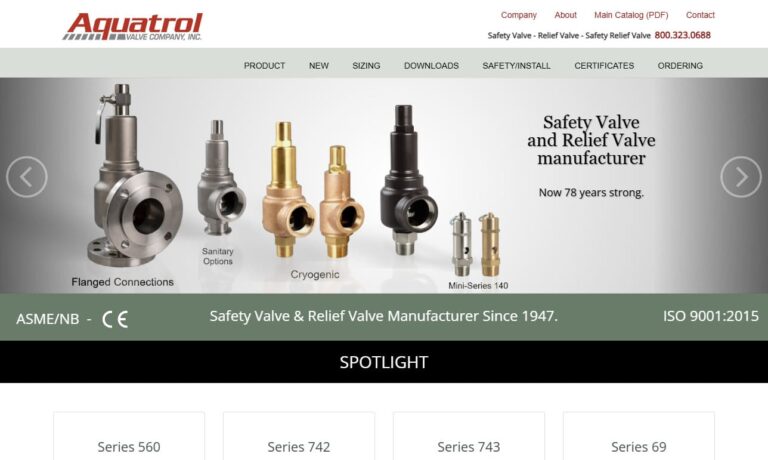

At Aquatrol, we take pride in being a trusted name in the design and manufacturing of high-quality check valves built for durability and precision. With decades of expertise, we have developed a deep understanding of fluid control systems and have dedicated ourselves to engineering solutions that ensure reliability and safety in even the most demanding industrial environments.

At SVF Flow Controls, we take pride in being a trusted manufacturer of precision-engineered flow control products, with a strong emphasis on quality, reliability, and performance. We specialize in the design and production of check valves, ensuring optimal flow management and protection for a wide range of industrial applications.

Offering a full line of flow control products, Plast-O-Matic Valves ensures high quality by testing each of our valve products individually before shipment. We offer plastic check valves, PVC check valves, relief valves, ball check valves and more. We are committed to engineering excellence.

More Check Valve Manufacturers

Check Valve Applications

Check valves are essential yet often overlooked components in nearly all plumbing and fluid transfer systems, spanning industrial, commercial, and residential settings. These critical devices serve as the primary means of backflow prevention, helping maintain smooth operations and system integrity across a wide spectrum of industries. Whether it’s managing water flow in municipal water systems, controlling process fluids in chemical plants, or protecting sensitive medical devices, check valves provide a simple yet reliable solution for ensuring unidirectional flow.

Key industries and sectors that rely on check valves include:

- Water and Wastewater Management: Used in sewage treatment, water purification, and municipal water supply systems to prevent contamination and ensure water quality.

- Healthcare and Pharmaceuticals: Essential for medical gas delivery, dialysis machines, and pharmaceutical manufacturing, where sterility and backflow prevention are critical.

- Chemical Processing and Power Generation: Check valves protect against reverse flow of hazardous or corrosive chemicals, and are indispensable in reactors, heat exchangers, and cooling systems, including in nuclear, thermal, and hydropower plants.

- Food and Beverage Processing: Maintain hygienic operations by preventing cross-contamination in bottling lines, filtration equipment, and CIP (clean-in-place) systems.

- Oil, Gas, and Petrochemicals: Used in upstream and downstream applications to prevent reverse flow in pipelines, compressors, and storage tanks.

- Agriculture and Irrigation: Protect pumps and irrigation systems from water hammer, back siphonage, and contamination.

- Chromatography and Laboratory Equipment: Maintain accurate sample delivery and prevent cross-contamination in analytical devices.

In residential settings, check valves are integral to water heaters, household plumbing, faucets, dishwashers, sump pumps, and advanced appliances such as metering pumps, blenders, mixers, and flowmeters. They seamlessly control start-stop functions, manage pressure surges, and prevent reverse flow that could cause leaks or equipment damage.

In industrial applications, check valves play a pivotal role in overseeing complex systems, including:

- Nuclear and Chemical Plants: Manage hazardous fluids, prevent leaks, and ensure compliance with environmental regulations.

- Aircraft Hydraulic Systems: Handle vibrations, extreme temperatures, and corrosive materials in flight-critical systems.

- Spacecraft and Launch Vehicles: Regulate reaction control, propulsion propellants, and altitude adjustments, where error-free operation is essential.

- Gas Stream Control: Prevent unwanted gas mixing in HVAC, cryogenics, and industrial gas supply networks.

Why are check valves so widely adopted? Their autonomous operation means no external energy source is required, making them a cost-effective and reliable solution for flow control, system protection, and regulatory compliance across a diverse range of applications.

Looking for application-specific check valves?

- What types of check valves are best for high-pressure applications?

- How do check valves help prevent contamination in potable water systems?

- What accessories enhance check valve operation in industrial settings?

The History of Check Valves

The evolution of check valve technology is a testament to innovation driven by industry need. Frank P. Cotter invented the first check valve in 1907, notable for its ease of installation, inspection, and repair. This early design paved the way for widespread adoption in both municipal and industrial water systems.

In 1916, Nikola Tesla developed the Tesla valve, later patented in 1920. Unlike traditional spring or swing check valves, the Tesla valve featured a fixed geometry that allowed fluid to move in one direction with minimal resistance while offering significant resistance to reverse flow—an ingenious design that found applications in emerging technologies of the time.

With advancements in plastic and manufacturing technology, plastic diaphragm check valves became prevalent, particularly in the medical industry, where chemical resistance and sterility are paramount. Over the decades, check valve design has evolved in response to increasingly stringent safety, environmental, and performance standards.

A pivotal regulatory milestone occurred in January 2014, when Congress enacted the Drinking Water Act, limiting the lead content in any object that contacts drinking water to 0.25%. This change compelled manufacturers to replace outdated, lead-based water supply piping systems with new components, including check valves made of plastic or stainless steel, ensuring safety and compliance in potable water systems.

Design of Check Valves

Check valves may appear simple in design and purpose—allowing fluid to flow in one direction while preventing backflow—but their development involves a complex interplay of engineering, material science, and application-specific considerations. The right check valve design ensures reliable performance, long service life, and seamless integration into a fluid system.

Material Selection: The Foundation of Performance

Every application exposes check valves to unique operating environments. One of the most pivotal considerations in check valve design is the choice of construction materials, which directly influences the valve’s longevity, efficiency, and resistance to operational stresses. Selecting the wrong material can lead to premature wear, erosion from abrasive media, or even contamination of the process stream—issues that could compromise system integrity or safety. To mitigate these risks, manufacturers draw from an extensive palette of materials tailored to specific environments and applications.

Material options include:

- Plastics: Polyvinyl chloride (PVC), polyethylene (PE), and polypropylene (PP) are prized for their corrosion resistance and affordability in water or chemical systems. PTFE (Teflon) is used where chemical compatibility and low friction are required.

- Metals: Brass and copper excel in residential plumbing due to their malleability and resistance to rust; ductile iron powers iron-bodied valves for heavy-duty waterworks; aluminum provides lightweight strength; carbon steel balances cost and toughness; and stainless steel—used in both valve bodies and springs—delivers superior resistance to corrosion and high temperatures (up to 400°C in some grades).

- Synthetics and Elastomers: Rubber (e.g., nitrile, EPDM, Viton) forms seals or diaphragms, ensuring flexibility and tight closure. These are critical in high-purity, sanitary, or low-pressure applications.

This material diversity is so significant that check valves are often named after their primary component—e.g., the iron body check valve or stainless steel check valve—reflecting how material choice defines their identity and application.

Sizing and Dimensions: Precision for Seamless Integration

Beyond materials, manufacturers devote considerable attention to the physical dimensions of check valves, which come in a vast array of sizes to suit different systems. The critical dimension is the diameter of the seat and stopping mechanism—the internal components that control flow—which can range from as small as 0.5 inches (12.7 mm) for compact residential fittings to several feet (e.g., 48 inches or 1.2 meters) for industrial pipelines.

Proper sizing ensures the valve integrates seamlessly into existing flow lines, matching the inner diameter of pipes or tubing. For instance, a 2-inch valve must align with a 2-inch pipe (nominal size, ~50.8 mm) to avoid flow restrictions or leaks. Sizing is based on detailed calculations involving pipe schedules (e.g., Schedule 40 or 80), wall thickness, and flow rates (measured in gallons per minute or cubic meters per hour). A mismatch—say, a 1-inch valve in a 2-inch line—could choke flow, while an oversized valve might not seal properly, undermining backflow prevention.

Manufacturers use standards like ASME B16.34 or ISO 5752 to guide these specs, ensuring compatibility and interchangeability across global systems.

Pressure Dynamics: Cracking Pressure and Flow Control

Valve size ties directly to another key factor: the pressure rating, often expressed as the cracking pressure—the minimum upstream pressure required to open the valve (e.g., 0.5-5 psi or 3.4-34.5 kPa). This is determined by the spring tension (in spring-loaded designs) or the weight of the disc (in swing or lift valves), calibrated to the system’s flow dynamics. An oversized valve in a low-pressure system won’t open, stalling flow even if backpressure is overcome. Conversely, an undersized valve might not close fully under insufficient differential pressure, allowing continuous flow or reverse leakage. Such failures risk equipment damage (e.g., pump cavitation), material loss, or hazardous cross-contamination.

Additional Design Considerations

Manufacturers also weigh several nuanced factors to fine-tune check valves:

- Media Temperature: Materials and seals must withstand operating ranges—e.g., PVC caps at 60°C, stainless steel at 400°C—lest they deform or fail.

- Differential Pressure: The gap between upstream and downstream pressure (e.g., 10-100 psi) affects closure speed and sealing effectiveness.

- Valve Flow Coefficient (Cv): Measures flow efficiency (e.g., Cv 50 = 50 GPM at 1 psi drop)—critical for high-flow systems like hydropower (Cv 500-1,000).

- System Cleanliness: In sanitary or food-grade systems, low dead volume and smooth internal surfaces are essential to prevent bacterial growth.

- Maintenance Access: Designs like wafer or swing check valves enable tool-free inspection and cleaning, reducing downtime.

These elements hinge on the valve type—e.g., ball, swing, or diaphragm—and the application, from residential faucets to nuclear reactors. For unique needs, manufacturers craft custom check valves, tweaking disc angles, spring rates, or exotic alloys (e.g., Hastelloy, Monel) for extreme environments.

Why It Matters

This meticulous design process ensures check valves don’t just work—they excel, preventing backflow disasters, minimizing downtime, and meeting industry standards such as API 594 or AWWA C508. In 2025, advancements in 3D modeling (e.g., SolidWorks flow simulation) and material testing (e.g., ASTM G65 wear tests) further refine performance and reliability, balancing cost with operational excellence.

From a 1-inch brass valve in a dishwasher to a 24-inch ductile iron giant in a sewage plant, every detail—material, size, pressure—keeps the flow in check and your system protected.

Need help selecting the right check valve design?

- Which check valve materials are best for corrosive chemical systems?

- What is cracking pressure and why does it matter for your system?

- How do you size a check valve for your pipe diameter and flow rate?

Features of Check Valves

Check valves are increasingly popular due to their straightforward design and ease of use. These valves operate entirely based on process flow, eliminating the need for additional actuating mechanisms or external controls. This self-actuating mechanism makes check valves highly efficient and low-maintenance compared to other types of flow control valves.

Typically, a check valve is a tubular device attached to the pump head on both the inlet and outlet lines. Inside, it is divided into upstream and downstream sections by a seat that extends from the cylinder walls, allowing the process stream to pass through. On the downstream side, a sphere, cone, disc, or similar component rests against the seat, with limited movement to prevent it from being carried downstream.

When the stream flows in the intended direction and reaches the required pressure, the plug is dislodged from the seat, allowing fluid or gas to pass through. As the pressure decreases, the stopper returns to the seat to block backflow. Gravity or a stainless steel spring mechanism typically drives this return movement, although increased downstream pressure can also reposition the device. This action prevents downstream materials from mixing with upstream materials, even under elevated pressure.

The specific stopper used depends on the type of check valve:

- Ball check valves use a sphere.

- Lift check valves use a cone or disc attached to a rod guide.

- Swing and wafer valves use one or more discs to seal the valve seat.

For more information on choosing a check valve type for your application, see the section below.

Types of Check Valves

The diversity of check valve types allows for tailored solutions to suit virtually every fluid control scenario. Each type offers distinct benefits for different media, pressure ranges, flow rates, and installation requirements.

Large Check Valve

Large check valves, also known as non-return valves, are essential components in a variety of industrial, commercial, and domestic applications. They ensure the safe and consistent downstream flow of diverse materials, including water, oxygen, fuel, acids, bases, sludge, slurry, and hazardous waste. Their robust construction supports high flow rates and resists wear in demanding environments such as municipal waterworks, wastewater treatment plants, and energy facilities.

Mini Check Valve

Mini check valves, or micro check valves, function similarly to their larger counterparts but on a much smaller scale. These valves precisely regulate unidirectional gas or fluid flow in confined spaces, making them ideal for applications requiring meticulous control—such as medical devices, analytical instruments, and miniature pneumatic systems.

Relief Valve

Relief valves, commonly referred to as safety relief valves, are robust devices designed to withstand chemical corrosion and continuous use. Typically constructed from PVC, stainless steel, brass, or aluminum, these valves are crucial for releasing excess, potentially hazardous pressure from closed-top vessels or piping systems. They remain closed until the set pressure is reached, ensuring safety and system integrity, and are widely used in boiler systems, chemical reactors, and pressurized storage tanks.

Ball Check Valve

Ball check valves use a loose ball as a stopper and are available in iron, plastic, or stainless steel. They regulate fluid flow and come in various types:

- Spring-loaded ball check valves: Feature a stainless steel spring to keep the ball closed, opening only when sufficient pressure is applied.

- Reverse flow ball check valves: Rely on reverse flow to return the ball to its seat and seal the valve.

- Three-way ball check valves: Use a ball, gate, or globe stopper in the valve’s center to manage flow in multiple directions. Learn more about ball check valves.

Disc Check Valve

A disc check valve is a type of check valve characterized by the use of a disc-shaped mechanism as its closure element. Disc check valves encompass various types, including lift check valves, swing check valves, butterfly valves, and wafer check valves. Each of these valve types possesses distinct operational characteristics and designs.

Lift Check Valve

Lift check valves, also referred to as piston check valves, are equipped with a disc, commonly known as a “lift,” that can move away from its seat. This disc lifts when the pressure of the inlet fluid or upstream fluid rises, allowing fluid to flow downstream. As the pressure decreases, either high downstream pressure or gravity forces the disc back to its seated position. These valves are frequently employed as safety relief or control valves, particularly in high-pressure steam, gas, or liquid lines.

Swing Check Valve

Swing check valves feature a flat disc that rotates or pivots on a hinge pin. Unlike other valve types, they do not require a stainless steel spring for operation. The disc swings onto the seat to prevent reverse flow and swings away from the seat to allow forward flow. These valves are also known as non-return valves and are widely used in water, sewage, and HVAC systems for their low pressure drop and simple operation.

Butterfly Check Valve

Butterfly check valves are engineered to manage pressure flow within large piping systems. These valves feature a tube-shaped disc that remains within the flow stream, regulating flow through rotational movement. They are available in either iron or stainless steel construction. Butterfly check valves are versatile and find applications across various sectors, including food and beverage, chemical, and pharmaceutical industries, where they offer a compact and cost-effective solution for large-diameter pipelines.

Wafer Check Valve

Wafer check valves are designed as one-way mechanisms to prevent backflow by permitting fluid flow in a single direction only. The valve operates by opening the disc with the forward fluid flow and closing it when backflow pressure is detected. Available in stainless steel or iron, these valves are essential for ensuring unidirectional fluid movement and preventing reverse flow, especially in compact or space-restricted installations.

Spring Check Valve

Spring check valves utilize a stainless steel spring to regulate the pressure required for valve actuation and ensure reliable closure. These valves are particularly effective in managing high-pressure differentials across the valve, preventing issues such as valve clapping and overflow caused by increased downstream flow. Additionally, they offer protection against strong upstream surges, including water hammer effects.

Double Check Valve

Double check valves integrate multiple valve components to enhance functionality and reliability. Generally made from materials such as stainless steel, plastic, or iron, these valves are designed to reduce wear and offer robust protection against backflow, which could otherwise cause pressure surges, cross-contamination, or flooding. By employing a dual-valve setup, double check valves provide an added layer of security, ensuring stable and effective system performance. Double check valve assemblies are often required by plumbing codes for backflow prevention in potable water supply lines.

Pilot-Operated Check Valve

The pilot-operated check valve features a compact, non-modular design and is optimized for handling high-pressure or high-flow conditions. Typically installed with a flanged connection or through metallic piping, it effectively prevents reverse flow while allowing smooth passage through the valve to an actuator. This type of valve is celebrated for its excellent sealing performance and is ideal for applications requiring secure clamping or holding. However, it is less effective for controlling the flow of overrunning loads and is not recommended for use with cylinders.

Solenoid Valve

Solenoid valves are compact, energy-efficient components that regulate fluid flow via an electrically activated solenoid. Typically equipped with two ports (2-way valves), these valves enable fluid to pass through unhindered when open and block it when closed. Three-way valves redirect fluid between an inlet port and one of two alternative ports, commonly used for exhaust or supply. In fluidics, solenoid valves are essential for precise operations such as mixing, halting, releasing, dosing, or distributing fluids, ensuring effective and reliable flow control.

Silent Check Valve

Designed for quiet operation, the silent check valve minimizes noise by rapidly opening and closing to reduce hammering effects. It mitigates shock and ensures a smooth process by closing before fluid flow reverses, making it ideal for high-rise building plumbing systems and other noise-sensitive environments.

Which check valve is right for your project?

- Are you looking for a check valve for potable water, chemical processing, or oil and gas applications?

- Need a valve to handle high temperatures, abrasive slurries, or hygienic processes?

- Is silent operation or compact installation space a top priority?

Advantages of Check Valves

Check valves, also known as non-return or one-way valves, are essential for maintaining efficient and safe system operation. Their unique ability to permit flow in only one direction while automatically preventing reverse flow protects critical processes and equipment across industries.

Key benefits of check valves include:

- Backflow Prevention: Protects pumps, compressors, and sensitive equipment from damage caused by reverse flow, contamination, or pressure surges.

- Flow Control: Maintains the correct flow direction and rate, supporting system stability and process consistency.

- Energy Efficiency: Eliminates the need for additional actuators or powered devices, reducing system complexity and operating costs.

- System Protection: Minimizes water hammer and pressure spikes that can damage pipes, fittings, and connected devices.

- Versatility: Adaptable to a wide range of fluids (water, gas, steam, chemicals) and installation configurations (vertical, horizontal, inline).

- Low Maintenance: Simple construction means fewer moving parts, reduced wear, and long service life with minimal upkeep.

- Compliance: Meets regulatory requirements for potable water, industrial safety, and environmental protection.

- Cost-Effectiveness: Provides an affordable solution for backflow prevention and process control, lowering total system costs.

In summary, check valves play a pivotal role in ensuring operational safety, process efficiency, and regulatory compliance, making them a cornerstone of modern fluid management systems.

Check Valve Accessories

Accessories for check valves play a crucial role in enhancing their overall performance, installation, operation, and maintenance. Selecting the right accessories can extend valve lifespan, reduce downtime, and improve system safety.

Common check valve accessories include:

- Flanges and Flange Gaskets: Establish secure, leak-proof connections between check valves and piping systems, ensuring system integrity and easy maintenance.

- Strainers: Positioned upstream of the check valve, strainers remove debris and contaminants from the fluid or gas stream, protecting both the valve and downstream equipment from damage.

- Bypass Lines: Maintain continuous flow or pressure relief when the check valve is closed, preventing system interruptions and ensuring operational flexibility.

- Silencers: Reduce operational noise and mitigate the water hammer effect, especially important in residential or sensitive commercial environments.

- Position Indicators and Gauges: Provide real-time monitoring of valve position, pressure, and temperature, allowing operators to ensure optimal performance and address issues promptly.

- Lubrication Systems: For valves with moving parts, lubrication systems reduce friction and wear, maintaining smooth operation and extending service life.

- Valve Lockouts and Tags: Secure check valves during maintenance or repairs, preventing accidental operation and enhancing workplace safety.

- Backflow Preventers: Often used in conjunction with check valves, these devices provide additional protection against reverse flow in critical plumbing and water supply systems.

The selection of specific accessories should be based on the requirements and characteristics of the system to maximize functionality, efficiency, safety, and control of check valves.

What check valve accessories does your system need?

- Do you require strainers to protect against debris in your process line?

- Are bypass lines or silencers necessary for your installation?

- Would position indicators help your maintenance team monitor valve status?

Choosing the Right Manufacturer

To obtain a high-quality check valve that meets your application’s requirements, it’s essential to collaborate with a reputable manufacturer known for technical expertise, quality assurance, and responsive customer service—especially for custom valve requests or specialized industries.

How to select the best check valve manufacturer:

- Review manufacturer profiles and certifications (e.g., ISO 9001, API, NSF).

- Request product documentation, test reports, and previous project references.

- Inquire about customization options for materials, sizes, and operating parameters.

- Assess after-sales support, warranty terms, and available technical resources.

- Compare responses from multiple suppliers to make an informed decision.

We’ve compiled a list of top check valve manufacturers with detailed profiles available midway through this page. Explore their offerings, reach out with your project specifications, and partner with a supplier dedicated to your success.

Ready to source check valves for your project?

- What certifications or standards are required for your industry?

- Do you need custom-engineered check valves or off-the-shelf solutions?

- What is your expected order volume and delivery timeline?

For more information or to request a quote, contact our featured check valve manufacturers today.

What are the primary applications of check valves?

Check valves are used in a variety of settings—including water and wastewater management, healthcare and pharmaceuticals, chemical processing, food and beverage production, oil and gas, agriculture, laboratory equipment, residential plumbing, and industrial systems. Their main function is to prevent backflow, ensuring unidirectional flow and system integrity.

How does material selection affect check valve performance?

Material selection directly influences a check valve’s efficiency, longevity, and chemical resistance. Options include plastics like PVC and PTFE for corrosion resistance, metals like brass, stainless steel, or ductile iron for durability and temperature tolerance, and elastomers like rubber for sanitary or low-pressure applications. Choosing the right material ensures reliable performance in specific environments.

What is cracking pressure and why is it important?

Cracking pressure is the minimum upstream pressure required to open a check valve and allow fluid flow. It is crucial for ensuring that the valve operates only under appropriate flow conditions. Setting the correct cracking pressure prevents improper sealing, backflow, and potential equipment damage in both low- and high-pressure systems.

What are the main types of check valves?

Common types of check valves include ball check valves, disc check valves (like lift and swing check valves), butterfly check valves, wafer check valves, spring check valves, double check valves, pilot-operated check valves, solenoid valves, and silent check valves. Each type is designed for specific flow, pressure, installation, and application requirements.

What are the advantages of installing check valves in fluid systems?

Check valves provide reliable backflow prevention, maintain flow consistency, protect equipment from pressure surges, offer energy efficiency by operating autonomously, require low maintenance due to simple design, and comply with industry safety and environmental standards. These benefits help reduce costs and improve operational safety.

Which accessories can enhance the operation and maintenance of check valves?

Common accessories for check valves include flanges and gaskets for secure connections, strainers to protect from debris, bypass lines to ensure uninterrupted flow, silencers to minimize noise, position indicators and gauges for monitoring, lubrication systems for smooth operation, valve lockouts for safety, and backflow preventers for added protection.

How do you choose the right check valve manufacturer?

Choose a manufacturer with relevant certifications (such as ISO 9001 or API), documented product testing, customization capabilities, strong customer support, warranty coverage, and a reliable track record. Compare offerings and technical resources from several suppliers to ensure you receive the best solution for your application.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services