Valves are adaptable machinery used to regulate the flow of gasses or liquids. They are crucial components in various piping and industrial systems, working to control flow and pressure in order to avoid a system backflow. A spring check valve works to prevent backflow by using a spring to apply pressure on a disk that closes the valve when required. Read More…

Our check valves are manufactured with the customer in mind. We believe in offering superior products and services every time. No matter whether you are looking for small or large valves, we can meet your every needs. It is our goal to offer excellent prices and service to each customer. Contact us to learn more today!

At Beswick Engineering Co., we are dedicated to engineering precision miniature fluid power components that deliver reliable performance in demanding applications. Our team specializes in designing and manufacturing high-quality check valves, along with an extensive selection of other fluid control products, all crafted to meet tight tolerances and rigorous performance requirements.

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

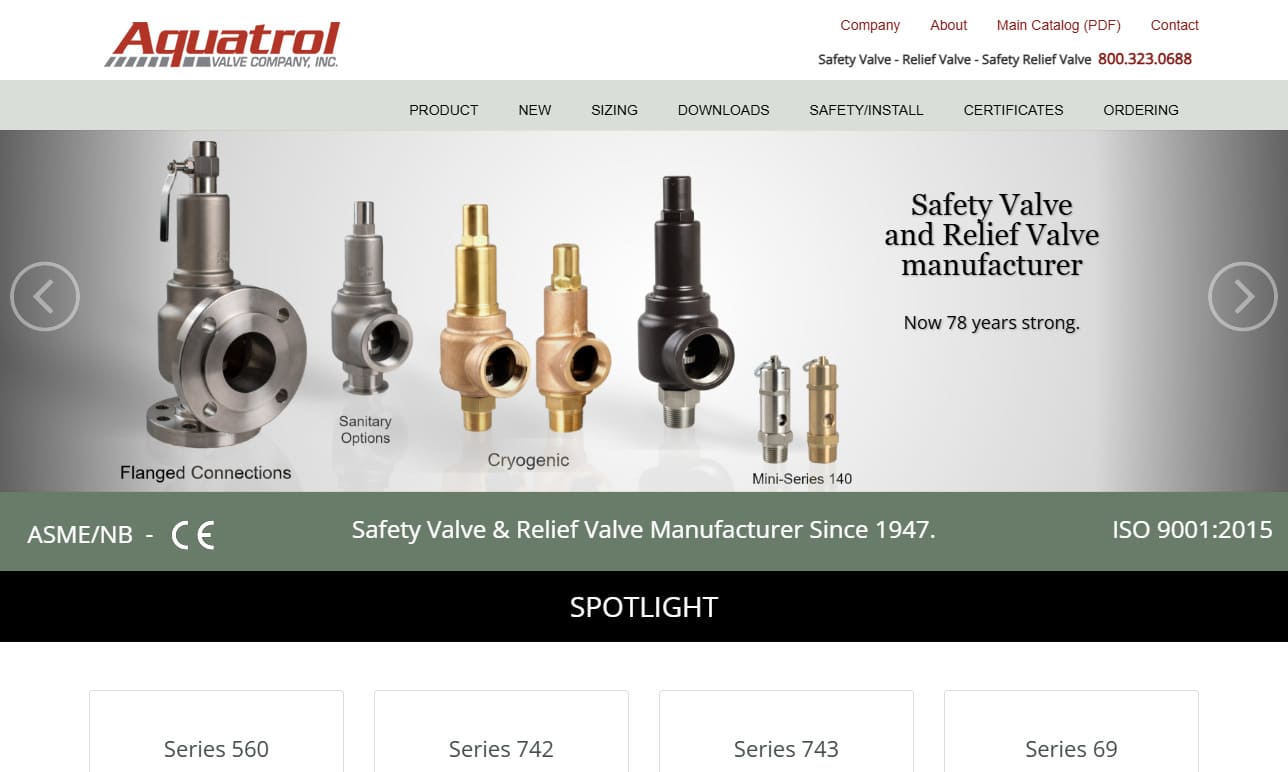

At Aquatrol, we take pride in being a trusted name in the design and manufacturing of high-quality check valves built for durability and precision. With decades of expertise, we have developed a deep understanding of fluid control systems and have dedicated ourselves to engineering solutions that ensure reliability and safety in even the most demanding industrial environments.

At SVF Flow Controls, we take pride in being a trusted manufacturer of precision-engineered flow control products, with a strong emphasis on quality, reliability, and performance. We specialize in the design and production of check valves, ensuring optimal flow management and protection for a wide range of industrial applications.

Offering a full line of flow control products, Plast-O-Matic Valves ensures high quality by testing each of our valve products individually before shipment. We offer plastic check valves, PVC check valves, relief valves, ball check valves and more. We are committed to engineering excellence.

More Spring Check Valve Manufacturers

Spring Check Valves: Comprehensive Guide to Types, Applications, and Selection

Spring check valves are essential components in fluid control systems, designed to guarantee one-way flow and effectively prevent unwanted reverse flow across a wide range of industrial, commercial, and residential applications. With a single input and output, spring check valves must be positioned precisely for optimal performance. All check valves, including spring variants, are marked with an arrow on their side, indicating the intended direction of fluid flow. These valves are also commonly referred to as non-return valves, one-way valves, or spring-loaded check valves.

Are you considering adding or replacing a spring check valve in your piping system? Read on to discover the different types, use cases, selection criteria, and factors that influence the optimal choice for your application. Learn how spring check valves enhance system reliability, reduce maintenance, and protect expensive equipment from damage caused by backflow.

What is a Spring Check Valve?

A spring check valve is a type of check valve that utilizes a spring mechanism to close the valve automatically when the forward flow ceases or reverses. The spring acts as a force against a movable disk or poppet, which opens when the upstream pressure (cracking pressure) overcomes the spring's resistance, and closes immediately when the pressure drops or reverses, thus preventing backflow.

- Key features: Unidirectional flow, spring-assisted closure, automatic operation, low maintenance.

- Common materials: Stainless steel, brass, PVC, bronze, cast iron, and other corrosion-resistant alloys.

- Typical applications: Water supply lines, chemical processing, oil and gas pipelines, HVAC systems, irrigation, wastewater treatment, pump systems, and more.

Types of Spring Check Valves

Spring check valves come in various designs to suit different pressure requirements, installation constraints, and fluid characteristics. Understanding the differences between each type can help you select the right valve for your specific industrial, commercial, or residential project.

Spring-Loaded In-Line Valves

Spring-loaded in-line valves employ a centrally located stem-disk assembly with a compression spring. These valves remain closed by default, with the spring pressing the disk firmly against the valve seat, blocking flow. To open the valve, the fluid’s pressure must exceed the combined force of the spring and any additional closing force (cracking pressure). Once the pressure drops below this threshold, the spring instantly pushes the disk back to its seat, ensuring immediate and reliable shutoff to prevent reverse flow.

Key advantages of in-line spring check valves include:

- Compact, streamlined design suited for confined spaces

- Consistent, rapid response to pressure changes

- Minimal maintenance requirements

- Versatility for both horizontal and vertical installations

In-line spring check valves are widely used in water distribution, process industries, and pump discharge applications where dependable backflow prevention is critical.

Spring-Loaded Y Valves

Spring-loaded Y check valves function similarly to in-line designs but feature a distinct “Y” shaped body. The spring and disk are positioned at an angle, which offers several advantages:

- Easy access for inspection, cleaning, or repair without removing the valve from the pipeline

- Smoother flow path with reduced turbulence

- Enhanced suitability for systems that require periodic maintenance

This configuration is especially popular in industries where downtime is costly, such as chemical processing, water treatment, and food and beverage manufacturing. The Y pattern allows operators to perform routine servicing efficiently, ensuring ongoing system reliability.

Foot Check Valves

A foot check valve, sometimes called a foot valve or ball check valve, is designed specifically for installation at the intake or suction point of a pump or piping system. These valves feature a ball or disk mechanism, and often incorporate a filter screen to prevent the entry of debris and contaminants.

- Prevents gravity-induced backflow when pumps are off

- Maintains pump priming by keeping the suction line filled

- Screen or filtration shield protects the pump and piping from particulates

Common use cases for foot check valves include:

- Well water pumping systems

- Ponds, swimming pools, fountains

- Sump pumps and drainage applications

- Hydraulic and pneumatic pump intakes

By reducing pressure losses and protecting sensitive components, foot check valves extend the life of pumps and minimize maintenance costs.

Wafer Check Valves

Wafer check valves are compact, lightweight valves designed to fit between two pipe flanges, saving space and reducing material costs compared to traditional swing or lift check valves. The valve consists of two half-circle disks hinged together, which fold open under forward flow and close securely to prevent backflow.

- Spring mechanism ensures quick, positive closure

- Low pressure drop and minimal flow resistance

- Suitable for horizontal and vertical installations

- Ideal for systems with tight installation spaces or where weight reduction is important

Wafer check valves are particularly popular in HVAC systems, fire protection loops, boiler feedwater, and chemical processing due to their reliability and cost-effectiveness. The spring is held in place by a retainer, ensuring precise operation even with fluctuating pressures. Their versatility makes them a preferred choice for engineers specifying backflow prevention solutions.

Silent Check Valves

Silent check valves—also known as poppet check valves or non-slam check valves—are engineered for quiet operation and to eliminate the water hammer effect. These valves incorporate a spring-assisted disk that closes gradually, preventing abrupt flow stoppages and associated pressure surges.

- Spring-assisted closure for noise reduction and smooth operation

- Helps control pressure spikes and water hammer in high-pressure water lines

- Used in potable water systems, high-rise building water supply, and sensitive process lines

Are you experiencing pipe noise or water hammer in your plumbing system? Silent check valves may be the ideal solution for you. Their advanced design protects sensitive pumps, meters, and downstream equipment from the damaging effects of fluid surges, ensuring long-term system stability.

Spring Check Valve Connections

Proper connection of spring check valves to the piping network is crucial for leak-free operation and system integrity. There are several standard connection types, each suited for specific installation and maintenance requirements:

- Threaded connections: Common in residential and light commercial applications for easy installation and removal.

- Flanged connections: Preferred in industrial pipelines for secure, high-pressure connections and straightforward serviceability.

- Welded connections: Used in critical or high-pressure systems where maximum leak resistance is required.

- Soldered (“sweat”) connections: Typical in copper piping systems, ensuring a strong, permanent bond.

When choosing a connection method, consider factors such as fluid pressure, temperature, ease of maintenance, and compatibility with your existing piping system. For additional guidance, see our resource: Check Valve Installation Best Practices.

Benefits of Using Spring Check Valves

Why choose a spring check valve over other types of check valves? The answer lies in their robust performance and operational advantages:

- Reliable backflow prevention: The spring mechanism ensures prompt closure, even at low flow rates, minimizing leakage and reverse fluid movement.

- Automatic, maintenance-free operation: Spring check valves require no external actuation or control, reducing maintenance costs and complexity.

- Wide compatibility: Suitable for a broad range of fluids—including water, oil, gas, chemicals, slurries, and more—across a variety of industries.

- Prevention of pump damage and water hammer: By stopping reverse flow, these valves protect pumps, compressors, and other equipment from costly damage and downtime.

- Long service life: Quality materials and design features allow spring check valves to withstand harsh operating conditions and frequent cycling.

- Versatile installation: Available in multiple sizes, materials, and connection types to meet diverse application requirements.

Are you searching for a dependable way to prevent reverse flow or water hammer in your system? Explore our full selection of spring check valves and solutions to find the perfect match for your project.

Common Applications of Spring Check Valves

Spring check valves are found in countless applications where fluid flow must be controlled and backflow prevented. Some of the most common use cases include:

- Pump discharge lines: Prevents fluid from returning to the pump, avoiding damage and maintaining system priming.

- Potable water supply: Ensures sanitary conditions by stopping contaminated water from flowing backward into clean supply lines.

- Boiler and heating systems: Maintains correct flow direction, prevents pressure surges, and protects sensitive equipment.

- Fire sprinkler systems: Guarantees system readiness by preventing water from draining or siphoning backward.

- Industrial process lines: Controls hazardous fluid movement and maintains safety in chemical and petrochemical plants.

- Irrigation and agricultural systems: Stops back-siphonage of fertilizers or contaminants into the water source.

- Wastewater and sewage treatment: Prevents cross-contamination and ensures unidirectional flow in complex piping networks.

Do you have a unique application or face challenging fluid control issues? Consult with our valve specialists for expert recommendations tailored to your system’s requirements.

How to Select the Right Spring Check Valve

Choosing the ideal spring check valve for your needs involves evaluating several key factors. Consider the following selection criteria to ensure optimal performance and long-term reliability:

- Material compatibility: Match the valve body and internal components to the type of fluid, its temperature, and chemical properties.

- Pressure and temperature ratings: Verify that the valve can withstand your system’s maximum operating pressures and temperatures.

- Size and flow capacity: Ensure the valve’s diameter and design accommodate required flow rates without causing excessive pressure drop.

- Connection type: Select the most suitable connection (threaded, flanged, welded, soldered) for your piping system and maintenance needs.

- Installation orientation: Some spring check valves are designed for vertical, horizontal, or universal mounting—confirm compatibility with your layout.

- Certification and compliance: For critical or regulated environments, ensure valves meet industry standards (e.g., NSF, API, ASME, ISO).

- Maintenance and serviceability: Y-pattern and other accessible designs make routine inspection and cleaning easier, reducing downtime.

Spring Check Valve Sizing Guide

Proper sizing is crucial for efficient valve performance. Undersized valves can restrict flow and cause excessive pressure drops, while oversized valves may not close properly under low flow conditions. For detailed sizing recommendations, see: Check Valve Sizing and Selection Guide.

Still unsure? Use our helpful prompts to narrow your options:

- What type of fluid will the valve control (water, oil, gas, chemicals)?

- What are the maximum and minimum operating pressures and temperatures?

- How frequently will the valve cycle open and close?

- Do you require a silent or low-noise valve to prevent water hammer?

- Is space limited, requiring a compact or wafer-style valve?

Maintenance and Troubleshooting Tips

While spring check valves are designed for long-term, maintenance-free operation, periodic inspection can help ensure peak performance and prevent system failures. Consider these best practices:

- Regular visual inspection: Check for leaks, corrosion, or signs of wear.

- Clean screens and filters: Especially on foot valves, to prevent clogging and maintain flow rate.

- Test valve operation: Verify quick and complete closure after pump shutdown or flow reversal.

- Replace worn components: Springs, disks, or seals may require replacement after extended use in harsh environments.

Frequently Asked Questions About Spring Check Valves

- How do spring check valves differ from swing check valves?

Spring check valves use a spring to force the disk closed, offering faster response and reliable shutoff at low flows. Swing check valves rely on gravity and flow, making them less effective in certain orientations or at low flow rates. - Can spring check valves be installed vertically and horizontally?

Yes, most designs support both orientations, but always check manufacturer recommendations for your specific model. - What is cracking pressure?

This is the minimum upstream pressure needed to open the check valve and allow flow. - When should I choose a silent check valve?

Use silent check valves in systems prone to water hammer or where noise reduction is a priority, such as high-rise plumbing or sensitive process lines. - What materials are best for corrosive environments?

Stainless steel, PVC, and high-performance alloys are recommended for aggressive chemicals or seawater applications.

Conclusion

In summary, spring check valves are critical for ensuring unidirectional flow and preventing backflow in countless systems. Their automatic, spring-assisted operation delivers dependable performance, protects equipment, and simplifies fluid control. From compact wafer styles to heavy-duty flanged valves, a spring check valve exists for virtually any application or industry.

Whether you're designing a new system or upgrading an existing one, selecting the right spring check valve involves considering fluid properties, system pressure, connection type, and installation conditions. Prioritize quality, compatibility, and ease of maintenance for the best long-term value.

Selecting the Correct Spring Check Valve Company

For the most beneficial outcome when purchasing spring check valves, it’s essential to partner with reputable spring check valve manufacturers and suppliers. Use our comprehensive directory of spring check valve suppliers to compare companies based on expertise, product range, certifications, and customer reviews.

- Each supplier’s profile highlights core competencies, manufacturing capabilities, and application specialties.

- Contact forms are available for direct inquiries, technical support, or requesting a quote for your specific requirements.

- Preview supplier websites and get a detailed overview of their offerings with our proprietary website previewer tool.

- Use our streamlined RFQ (Request for Quote) form to efficiently reach multiple manufacturers with a single submission, saving time in your procurement process.

Are you ready to source the best spring check valve for your project? Compare top spring check valve companies now and connect with industry leaders for expert solutions, competitive pricing, and reliable after-sales support.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services